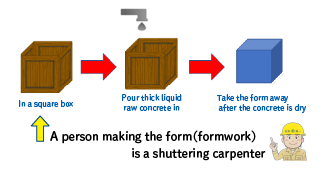

Building forms for reinforced concrete

We build forms to pour raw concrete used for reinforced concrete buildings and work pieces.

The form is called “KATAWAKU" (form/molding box), and a carpenter who makes the form is called “KATAWAKU-DAIKU” (shuttering carpenter).

Concrete is made with mixed cement and water which is liquidly at first. The concrete gets poured into a form and then cement and water cause chemical reaction to solidify.

The solidification takes a day to have the surface hardened, and to have it fully hardened consisting with the full strength of concrete takes approximately 4 weeks. While concrete is hardening, the forms get taken away after a week. Concrete section holds huge responsibilities of a building’s safety; therefore, it is extremely important to create safe and solid forms.

If forms are not precisely structured, concrete will not be able to create full strength and a building will not be able to hold safely. When structuring a form, perpendicular precision must be ±3㎜ and it is done by human hands instead of computers and robots.

It is completely professional skills utilized to create artistic and safe buildings.

Formworks are not only for buildings

There are more construction scenes where forms are required. Forms are necessary to build retaining walls, concrete made objects, and structure of playground equipment. Building a curving wall requires highly skilled hard work, knowledge, and experiences. TADAO ANDO (world famous architect) has various creations using exposed concrete finishing method. The method leaves concrete surface as itself. Formworks are necessary for many creations.

Recruitment information

Click HERE to information page.Feel free to contact us.